Many e-commerce sellers have faced the

problems such as below..

Inaccurate

Inventory Management

Inefficient

Order Picking

Overdependence on senior employee during order picking

Prone to fulfill

the wrong items

Increase labor

cost

Unable to measure employees’ performance

PayRecon SMART WMS Process Flow

RECEIVING

Create PO to record and verify the incoming stock thru PayRecon system to ensure the quantity is right and auto sync new quantity up by stock adjustment.

PUTAWAY

Moving the incoming stocks from the staging area to the right storage location.

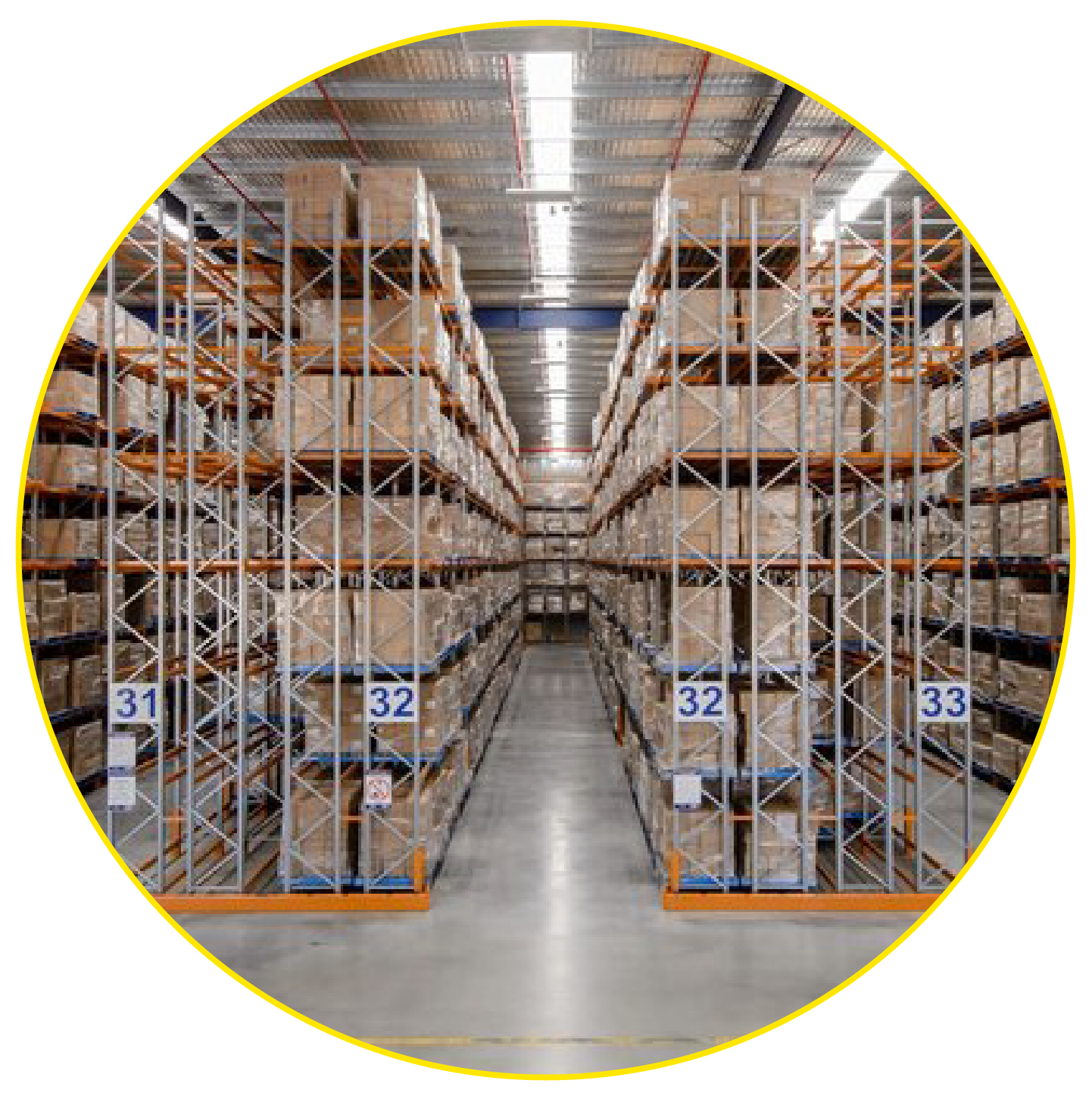

STORAGE

Store the incoming stocks and assign hot selling items to the pick face area that are moving out fast for faster picking.

ORDER PICKING

By using PDA or SMART Scan Mobile App, picker will receive the pick list and grab the trolley to pick the items by scanning the item’s QR Code or barcode.

ORDER SORTING

Sort the customizable shipping labels to diffrent bins based on orders.

ORDER PACKING

Packer scan item’s code to verify the correct item and quantity. After, wrapping and sealing the items, the relevant shipping label will be attached to the order packaging.

SHIPPING

Lastly, group orders based on courier company and generate carrier manifest to be signed by courier to serve as a record or proof of delivery.

9 Reasons to use PayRecon SMART WMS

> 3 Custom Picking

Methods

SMART POS System

[Retail]

Support PDA/

Smartphone for picking

Monitor employee’s

KPI anytime

Suitable for fulfillment

or dropshipping

Set ‘Pick Face Area’ for

hot selling items

Multi- warehouse

Generate Carrier

Manifest

Marketplace Quantity

Sync

Onsite Warehouse Visits,

Consultation and Implementation

Let PayRecon solve your warehouse management issues

-

Thank you for registering!

Be patient. Our people will contact you soon.

*Terms & Conditions applied.